Mold manufacturers should use new technologies to design

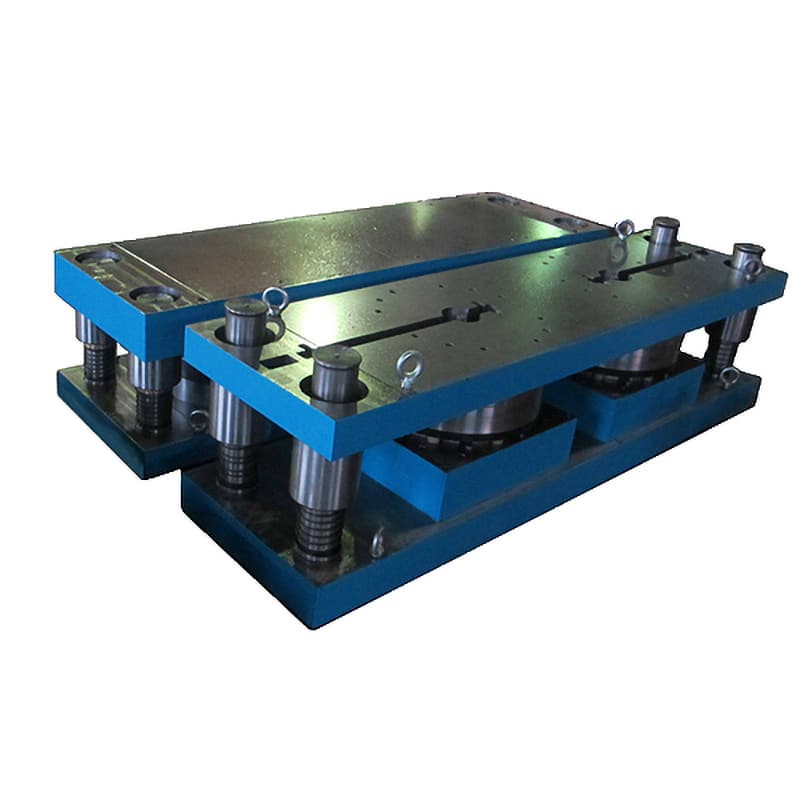

During the manufacturing process, the mold is used to shape the solid material into the desired shape. In most cases, these tools are customized to the item. They are also used in the stamping process. In addition to the shaping ability, the mold is also a heat-resistant device. They are usually made of tool steel or alloy steel with a high carbon content. Various other materials were also used, including wood and silicone.

Mold manufacturers should adopt new technologies in design, rapid prototyping and surface coating. These technologies help improve the efficiency and quality of end products. They are also capable of producing molds with micrometer-scale accuracy. With modern technology, mold makers are able to create highly specialized molds that can perform multiple operations at once.

A mold is a heat-resistant steel block used for metal forming. These tools are used in forming processes such as sheet metal and automotive body parts. They are also used for cutting, grooving and bending materials. In addition, they are used to make jewelry. Die-stamped jewelry is extremely durable, dense, and imperforate.

When designing a die casting mold, the shape of the part must match the shape of the mold. Likewise, the size of the part must match the size of the mold. The geometry of the mold affects the draft slope and draft strength of the mold. This is important to ensure that the casting can be smoothly removed from the mold. The shape of the mold wall also affects the draft slope. In order to ensure that the molten metal can exit at the correct angle, the depth and angle of the wall must be considered.

To ensure that parts are cast correctly in the mold, the casting process must be carefully monitored. This includes controlling the temperature of the molten metal, the draft angle, the pressure in the pressure chamber, and the pressure in the mold. Heat treatment should also be carefully considered. If there are holes in the mold, they should be tapered to minimize the possibility of shrinkage.

Mold makers must also choose the material of the mold carefully. Materials such as tool steel and alloy steel are highly resistant to high temperatures and wear, and are also corrosion-resistant. In addition, the alloy composition of the metal will also affect the entire process. If the type of molten alloy is different from the mold, it will also have an impact on the casting process. Some molds are also made of plastic or epoxy resin.

In addition, die-casters are responsible for performing secondary processes such as grinding holes and polishing surfaces. Some manufacturers also add brand names or product logos to die casting molds, which may also increase production costs. Additionally, some manufacturers install exhaust plugs in deep cavities.

Recommended Products

EN

EN

中文简体

中文简体 English

English