Using a can flipper can help you form the edges of your cans.

Using a tin can piping machine can help you shape the edge of the can. There are many different ways to make piping, and it's important to understand which method is right for your operation. Some common methods include piping, necking, and hemming. These methods work with each other to create a jar that looks great.

The flange is the part of the tank body that is perpendicular to the tank wall. It is also called “flange”. It connects the can body to the top or bottom of the can, depending on the type of closure. The flange is also used in conjunction with other techniques such as stitching to make the jar more durable. It is important to understand the difference between flange and stitching. The flange is formed before stitching. It can be manufactured using different techniques and can be used in conjunction with a can stapling machine.

Common flange manufacturing methods are known as the rotating flange method, which allows the use of thinner tinned sheets and ensures higher hardness. The flange edge of the swivel flange also features a contoured design to help prevent cracking. These flange heads are also rust-resistant, which is very beneficial for your operation. Rotating flanges are a modern method of manufacturing flanges. It is also the choice of manufacturers when making tin cans.

Another method of making flanges is by the “extruder” method. This method utilizes a blade to form a flange. Not only is it suitable for manufacturing flanges, but it also allows you to achieve high production speeds. However, the “extruder” method is only applicable to round tanks.

An automatic canning machine designed to achieve a user-friendly and maintenance-free operating mode. It is also capable of producing cans of various shapes and sizes. The machine has a modular design that allows you to easily change the size of your product. The machine can also be equipped with features such as a computerized paint delivery system, which helps the machine operate continuously. It can also be connected to an automatic sealing machine to complete the entire process. Using a can ring piping machine can help you produce dust- and rust-resistant cans. It can be customized according to the size of the can.

It is also important to remember that you can use a crimping machine to produce round cans of the type. This is important because crimping is essential for the sealing operation. The can must be crimped at both ends before sealing. The hemming machine is an essential piece of equipment for tin can manufacturers. The machine is dust and rust resistant and can be customized according to the type of can. It can also accommodate a variety of different types of cans, including square and rectangular cans. It is also very useful for manufacturers of non-cylindrical cans.

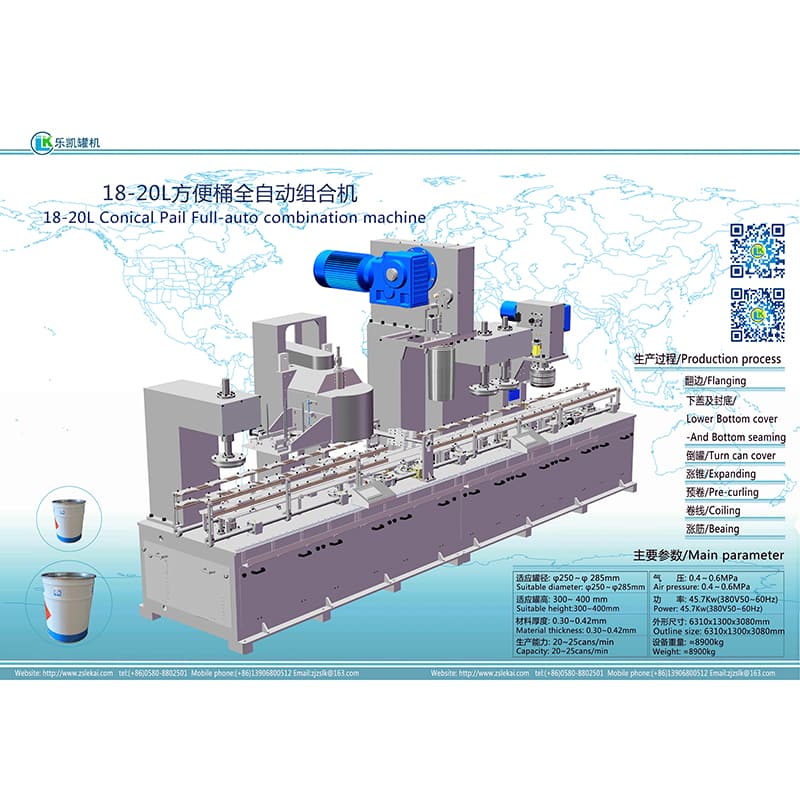

18-20 L Automatic Convenient Bucket Combination Machine

Name: Fully automatic and convenient cartridge combination machine

Tank diameter: 250 - 285 mm

Tank height: 300 - 400 mm

Iron surface thickness range: 0.3 to 0.42 mm

Production capacity: 20 to 25 pcs per minute

Motor power: 45.7 kW

Size: 6230×1300×3080 mm

Weight: 8900 kg

Recommended Products

EN

EN

中文简体

中文简体 English

English