Which automatic sealer is better? What are their advantages?

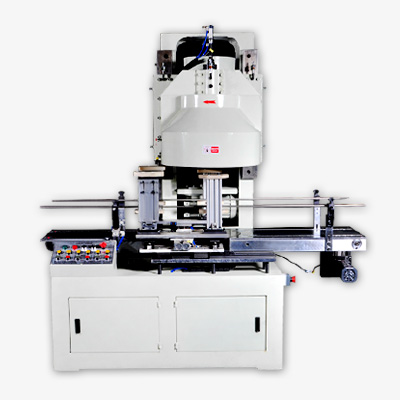

Which automatic sealer is better? Zhoushan Dinghai Lekai Canning Machinery Factory is a manufacturer specializing in the production of a complete set of mechanical canning equipment and molds. It offers equipment such as stretching machines, seam opening machines, automatic sealing machines, edge pressing machines, three-roller cylinder machines and hydraulic cone machines, and can also customize other equipment according to customer needs.

Automatic sealing machines are commonly used on automated and mass production lines. Since its models evolved from drilling machines, most of the sealing machines in China are currently large and heavy sealing machines. Due to its high cost, large output and high technical requirements, it is highly favored by large enterprises.

The automatic sealer is a high-cleanliness sealing device used for all reactive nitrogen fillings and milk powder packaging. It is a new sealer design in the health product packaging industry. The machine is a single-head sealer, and its preliminary design of five additional sealers has been improved, which has greatly improved production efficiency.

Sealing Machine This equipment enables sealing and mineralization treatment. This equipment makes up for the lack of high-speed sealing machines in China for sealing large milk powder cans, fully meets the needs of large and medium-sized enterprises, and is a product. The equipment is mechatronic controlled and has complete power, active operation in the tank, fully active and sealed aeration and nitrogen filling processes, and no purification treatment is required for all operations.

Electric, pneumatic and other types of actively replaceable sensor assemblies are all configured as a whole using advanced sensor assembly components from Schneider, Omron, Festo and abroad, which are highly actively replaceable and have strong and reliable performance.

The process parameters of the automatic sealing machine can be easily designed and changed according to different wheel groove type sealing needs on glass. The synergistic effect with the second sealing roller enables the flange of the sealing body to rotate synchronously with the hook of the can lid, seal the pressure and form a strictly parallel five-layer tin weld. Among them, the sealing wheel is particularly important because it determines the state of the flange and stack and the good fit of the hook and groove. The second sealing disc is the initial connection made after pressure is applied and sealing is completed. Symmetrical primer and two-character construction provide more stable sealing quality for large cans. The system enables can sealing operations without the need for a steam box as equipment, which increases the cost of the product and extends the shelf life of the can.

At a time when market competition is fierce, the issues of product packaging and diversity have naturally become the focus of much attention. To meet customer needs, the renowned Italian company Smee Decoration (whose influence is in the industry) has become a leader in packaging machinery and equipment for the food and beverage industry for decades to come. Smee's packaging equipment can be used for sealing in soft drinks, alcoholic beverages, food, cooking oil, dairy products, canned food, detergents, cosmetics and other industries, and has become the second largest packaging equipment supplier. Smee's diversification presents an opportunity for the market's demand for product updates: this includes not only the expansion of the machine range but also the diversification of machine functions.

Company website:http://www.zslekai.com/

Contact:

Contact Person: Mr. Li

Mobile phone: 13906800512

Tel: 0580-8802501

Fax: 0580-8803939

Address: No. 5, Huatian Road, Laotangshan, Dinghai District, Zhoushan City, Zhejiang Province

Dinghai Lekaican Machinery Factory is located on the coast of the East China Sea, in the beautiful and rich Zhoushan Islands——Dinghai Cengang Laotan Mountain, located in Zhoushan City, adjacent to National Highway 329, is just across the water from Putuo Mountain, one of the four major Buddhist temples in China, which is connected to each other by water and land. Convenient transportation. Established in 1992, Dinghai Lekaican Machinery Factory is a manufacturer specializing in the production of complete sets of mechanical can making equipment and molds.

Our factory has always adhered to the corporate purpose of “pursue, not seek, strive for”. In actual operation, we are constantly reforming and innovating, striving to improve our own level, strictly managing quality, ensuring stable and reliable product quality, improving the after-sales service system, and committed to providing 24-hour technical support. Products are subject to a three-pack policy within one year. Over the years, our factory has continuously improved products with strong technical strength and rich professional experience, winning the trust of customers with quality and service. Customers across the country enjoy a high reputation and visibility in the canning industry.

Recommended Products

EN

EN

中文简体

中文简体 English

English