Product

- Convenient barrel production line

- 18 L Square Tank Production Line

- 1-5 liter square tank production line

- 1-5 liter round can production line

- Tea cans, craft cans (square cans)

- 18.5 Conical coating barrel production line

- 18.5 Straight Paint Bucket Production Line

- Vacuum cleaner [housing] complete set of equipment

- 50 L Chemical Barrel Production Line

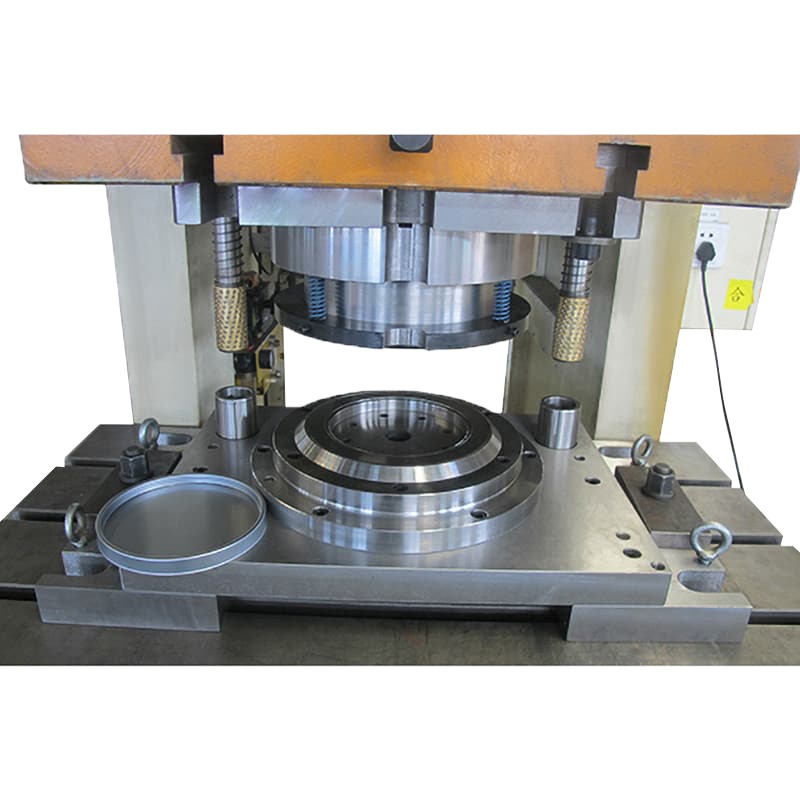

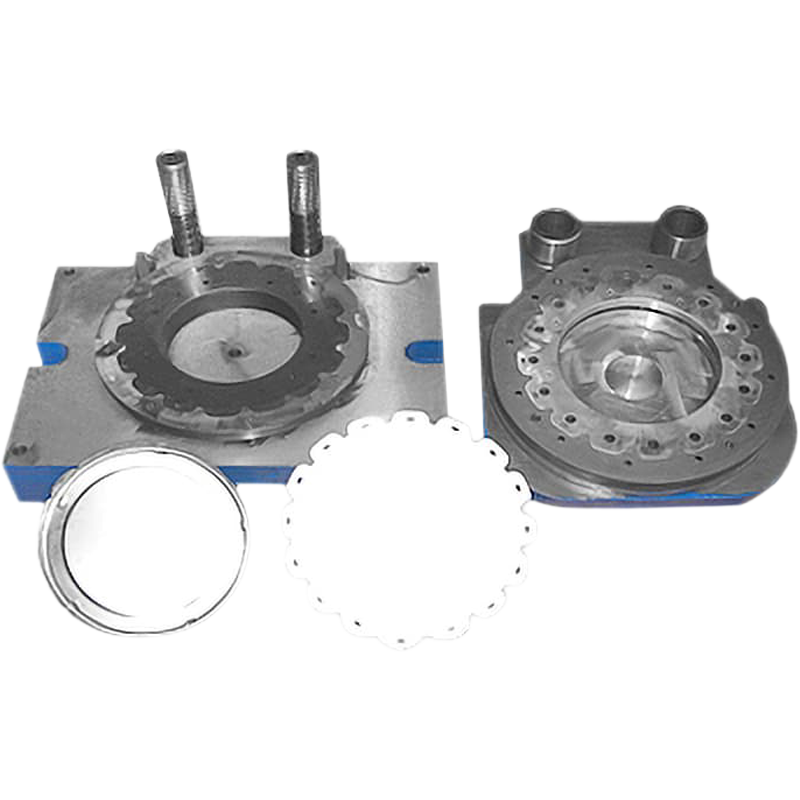

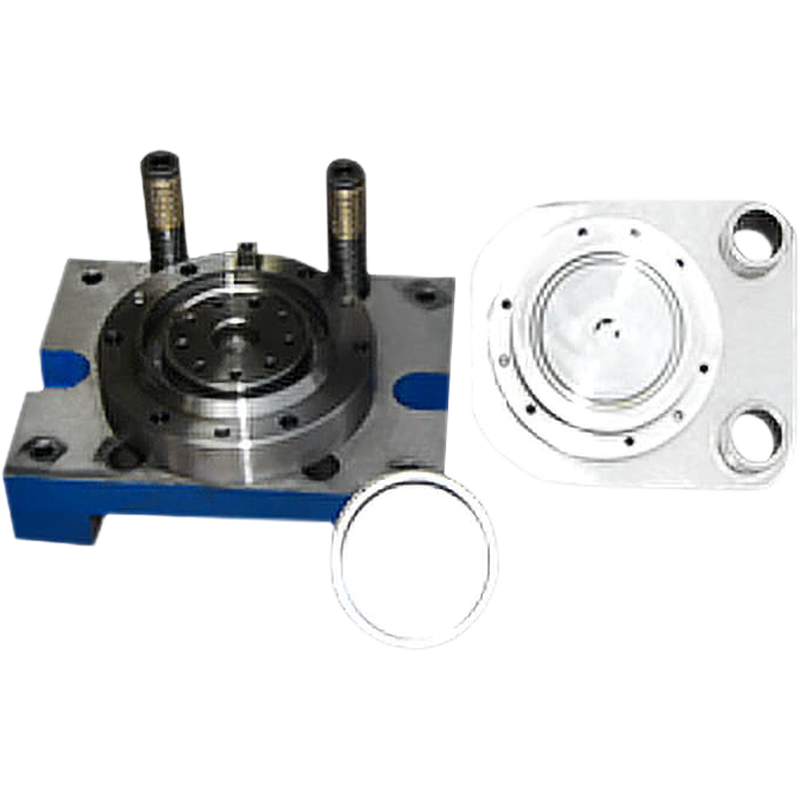

- Forming mold

- Can lid production line

- 18-20 liter barrel production line

Watch the video

About LK Machinery

LK MACHINERY CO., LTD. is an enterprise integrating industry, trade and technology. We specialize in the production of metal packaging equipment and the design of forming machinery. LK MACHINERY attaches importance to product quality and customer feedback. Products are exported to Russia, UAE, Saudi Arabia, Morocco, Uzbekistan, Kazakhstan, India, Indonesia and other countries. We have received several government innovation awards and hold a national patent.

-

0+

Industry experience

-

0+

Plant area

-

0+

Company Equipment

Certificate

News Updates

EN

EN

中文简体

中文简体 English

English