- Home

- About us

- Product

- Convenient barrel production line

- 18 L Square Tank Production Line

- 1-5 liter square tank production line

- 1-5 liter round can production line

- Tea cans, craft cans (square cans)

- 18.5 Conical coating barrel production line

- 18.5 Straight Paint Bucket Production Line

- Vacuum cleaner [housing] complete set of equipment

- 50 L Chemical Barrel Production Line

- Forming mold

- Can lid production line

- 18-20 liter barrel production line

- Service

- News

- Contact Us

Menu

- Home

- About us

- Product

- Convenient barrel production line

- 18 L Square Tank Production Line

- 1-5 liter square tank production line

- 1-5 liter round can production line

- Tea cans, craft cans (square cans)

- 18.5 Conical coating barrel production line

- 18.5 Straight Paint Bucket Production Line

- Vacuum cleaner [housing] complete set of equipment

- 50 L Chemical Barrel Production Line

- Forming mold

- Can lid production line

- 18-20 liter barrel production line

- Service

- News

- Contact Us

Product Search

Exit

- Convenient barrel production line

- 18 L Square Tank Production Line

- 1-5 liter square tank production line

- 1-5 liter round can production line

- Tea cans, craft cans (square cans)

- 18.5 Conical coating barrel production line

- 18.5 Straight Paint Bucket Production Line

- Vacuum cleaner [housing] complete set of equipment

- 50 L Chemical Barrel Production Line

- Forming mold

- Can lid production line

- 18-20 liter barrel production line

- Convenient barrel production line

- 18 L Square Tank Production Line

- 1-5 liter square tank production line

- 1-5 liter round can production line

- Tea cans, craft cans (square cans)

- 18.5 Conical coating barrel production line

- 18.5 Straight Paint Bucket Production Line

- Vacuum cleaner [housing] complete set of equipment

- 50 L Chemical Barrel Production Line

- Forming mold

- Can lid production line

- 18-20 liter barrel production line

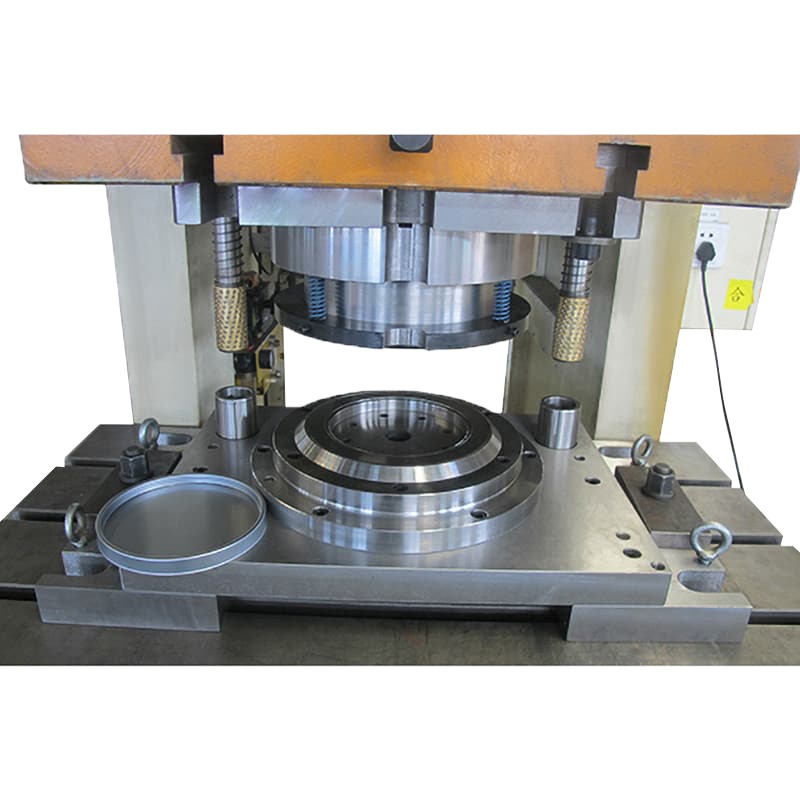

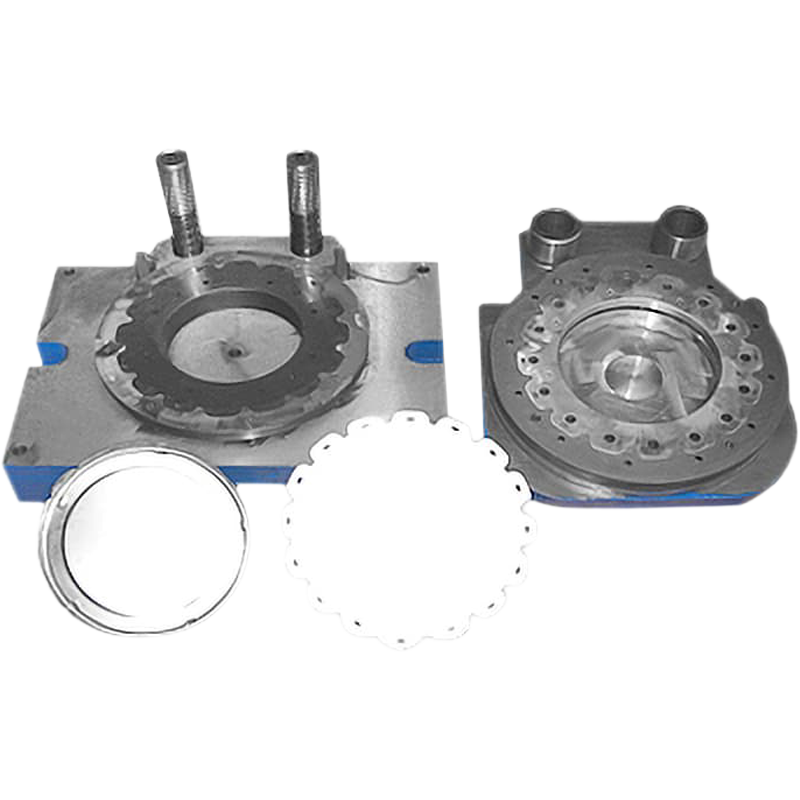

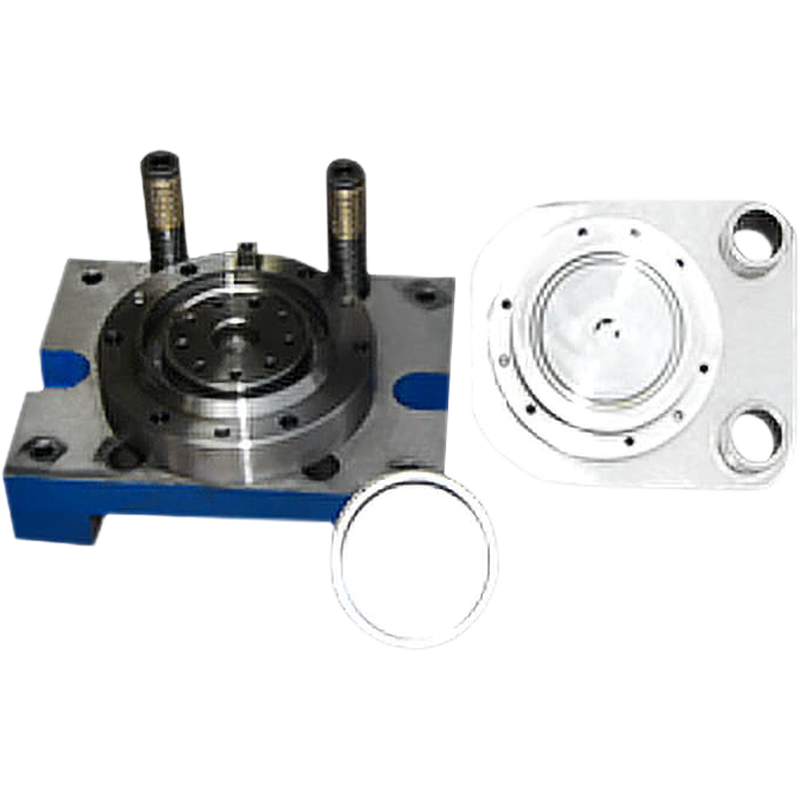

Tin can molds are tools used in the tin can manufacturing process. Tin cans are cylindrical containers made of tinned thin steel plates. Molds used to make tin cans are typically made of high-strength steel and are used to cut and shape steel sheets to obtain the desired shape. The tin can manufacturing process begins by feeding rolled thin steel sheets into a series of machines to form the tank body. The first step is to cut the steel plate into a round shape by a punch. The steel sheet is then molded into the tank form by a series of stamping processes using a mold. Depending on the tank size and type, the size and shape of the mold used also vary.

After the tank body is formed, the tank cover installation and sealing process needs to be completed through multiple equipment. The can lid is fixed using a “double sealing ” process—— to press the can lid into the can body and seal it. The surface of the tank is coated with a tin layer to prevent corrosion of the steel.

-

0+

Industry experience

-

0+

Plant area

-

0+

Company Equipment

-

04. 26. 2024What are the significant advantages of automatic winding and sealing machines compared to traditional sealing methods?View more

High efficiency: The automatic winding and sealing machine adopts advanced automation control system, which can realize continuous and high-speed sealing operation. Its efficient workflow, from the automatic supply of packaging materials and the precise execution of sealing operations to the automatic output of finished products, does not require excessive human intervention. This automated process significantly reduces the time per packaging cycle and improves overall production efficiency. In contrast, traditional manual or semi-automatic sealing methods have many bottlenecks during operation, such as operator proficiency, fatigue, and speed limitations of the sealing equipment, which limit the improvement of their efficiency. The high efficiency of automatic winding and sealing machines meets the urgent need for high efficiency and high productivity in modern production. Especially in large-scale, high-standard production environments, the advantages are even more significant.

High precision: The automatic winding and sealing machine is equipped with advanced sensors and control systems to ensure that the position and quality of each seal are accurate. Through precise algorithms and mechanical structure design, the automatic winding and sealing machine can accurately identify and locate different packaging materials, thereby ensuring the accuracy of the sealing position. At the same time, it can automatically adjust the sealing temperature and pressure according to the characteristics of the packaging material to achieve the sealing effect. This high-precision sealing method can effectively avoid errors and instabilities caused by human factors and improve the consistency and aesthetics of product packaging.

Stable sealing quality: Automatic winding sealers ensure the stability and consistency of sealing quality by precisely controlling parameters such as sealing temperature, pressure and speed. Its advanced control system can automatically adjust the sealing parameters according to different packaging materials and sealing requirements to achieve the sealing effect of. This precise control method not only reduces product losses but also improves the overall quality of product packaging. In contrast, conventional sealing methods often have difficulty achieving this degree of precise control and are prone to problems such as loose seals and air leaks, which affect product quality and safety.

Save labor costs: Traditional sealing methods usually require a lot of manual operation, which not only increases the company's labor costs, but is also susceptible to human factors, leading to quality fluctuations. Automatic winding and sealing machines can partially replace human labor and achieve automated operation. By reducing their reliance on manpower, companies can reduce labor costs while improving production efficiency and product quality. In addition, automatic winding and sealing machines can also reduce production accidents and quality problems caused by human factors, further reducing the company's operational risks.

Strong adaptability: The automatic winding and sealing machine has a wide range of applicability and can adapt to packaging items of different sizes and shapes. Whether it is large goods or small products, effective sealing can be achieved by adjusting machine parameters. This adaptability has led to the widespread use of automatic winding and sealing machines in many industries (such as food, medicine, chemical industry, etc.). Traditional sealing methods often require replacement and adjustment according to different packaging items, which is tedious and inefficient.

Highly safe: Automatic winding and sealing machines are designed and manufactured with operational safety in mind. It uses a variety of safety protection measures, such as automatic power off, overheat protection, etc., to ensure the safety and reliability of the operation process. At the same time, the automatic winding and sealing machine is also equipped with an emergency stop button and a fault alarm system so that it can stop quickly and perform fault troubleshooting in an emergency. These safety measures effectively reduce the risk of operator injury due to improper operation and improve the safety of the production environment.

Environmentally friendly and energy-saving: Automatic winding and sealing machines usually adopt energy-saving design and reduce energy consumption by optimizing the electrical system and mechanical structure. In addition, it can reduce the generation and waste of waste materials and meet the environmental protection requirements of modern society. As environmental awareness continues to grow, more and more companies are paying attention to the environmental performance of production equipment. As high-efficiency and energy-saving packaging equipment, automatic winding and sealing machines are increasingly favored by many companies. -

04. 18. 2024What is the main working principle of three-roller circular press?View more

The main working principle of the three-roll rounding machine is based on the plastic deformation principle of the material. Through the precise coordinated operation of the three rollers, the metal sheet is continuously rolled and rounded to form a circular tank that meets the requirements. Three-roll rounding machines require a series of preparations and adjustments before they can be put to work. Operators precisely adjust the spacing and angle of the three rollers according to the required diameter and height of the tank. The position and spacing of the working and reducing rollers determine the stress and deformation of the metal sheet during rolling, so the adjustment process requires great care and precision.

When the machine is started, the work rolls begin to turn and feed the metal sheet into the rolling area. The thin plate is subjected to strong pressure and friction between the working roller and the reducing roller, which causes plastic deformation. The function of the reducing roller is to further compress and plasticize the sheet, gradually thinning it and changing its shape.

During the rounding process, the metal sheet is continuously pushed forward by the roller and is subjected to continuous rolling pressure. The plate gradually changes from flat to round, and through the continuous action of three rollers, the required tank diameter and shape are finally obtained. During the entire rolling process, the operator needs to always pay attention to the operating status of the machine and make necessary adjustments according to actual conditions. For example, depending on the material and thickness of the sheet, it may be necessary to adjust the pressing force of the pressure reducing roller or the rotation speed of the working roller to obtain a rounding effect.

After finishing the finishing operation, the operator needs to stop the machine and carry out subsequent finishing work. This may include cleaning the work area, checking the condition of the machine, and preparing the materials and tools needed for the next process.

In general, the core of the working principle of the three-roller rounding machine is to use the coordinated movement of the rollers to achieve continuous rolling and rounding of metal sheets. During this process, precise adjustment, reasonable operation and timely maintenance are key factors to ensure the rounding effect. Through continuous technological improvement and innovation, the three-roller rounding machine has become one of the indispensable and important equipment in the metal processing industry. -

04. 12. 2024Hydraulic taper processing equipment is produced at a rate of 12 to 15 pieces per minute. Is this production rate stable?View more

The production capacity of the hydraulic conical reamer (model: lk/yzv180) has been set at 12 to 15 pieces per minute. In practice, this production capacity is usually stable, but it is also affected by many factors.

First, the stability of equipment is undoubtedly a key element in ensuring that its production capacity can continue to be utilized. For the hydraulic cone type expander (model: lk/yzv180), the design concept and manufacturing process fully reflect the high attention paid to stability. The equipment uses advanced hydraulic technology and achieves precise adjustment and stable maintenance of equipment operating parameters through a precise hydraulic control system. Whether it is the expansion speed, pressure control or working cycle, it can be precisely controlled through the hydraulic system to ensure that the equipment always maintains stable performance during long-term operation. The mechanical structure of the hydraulic cone expander has also been carefully designed and optimized. The use of high-quality materials and manufacturing processes ensures the accuracy and durability of the various components of the equipment. In particular, high-strength and wear-resistant materials are used in key components such as expansion heads, drivetrains and support structures to improve the overall stability and reliability of the equipment. Since hydraulic conical expanders are equipped with these advanced hydraulic systems and sophisticated mechanical structures, they can maintain a high degree of stability and reliability during operation. This means that under normal operating and maintenance conditions, the device can operate stably according to the set parameters without obvious performance fluctuations or failures. This provides users with stable and reliable production capacity and ensures the continuity and efficiency of the production process.

In practical applications, many factors such as material properties, operating technology, and equipment maintenance also need to be considered. However, in any case, the stability of equipment is always the basis for maintaining the stability of production efficiency. Therefore, choosing a hydraulic cone reamer with high stability is of great significance to ensure the smooth progress of the production process and improve production efficiency. However, production efficiency is also affected by some external factors. For example, variations in material properties, thickness, and size, as well as operator proficiency and skill level, can have an impact on production efficiency. If the material quality is unstable or not handled properly, it may lead to reduced production efficiency and fluctuations in production efficiency.

During the long-term operation of the equipment, various components will show wear and aging. If maintenance and repairs are not performed promptly, performance degradation or even failure may result. Therefore, it is crucial to regularly inspect and maintain the equipment. This includes cleaning dirt and dust from equipment surfaces, checking the oil level and quality of the hydraulic system, replacing worn parts, and adjusting various parameters of the equipment.

Through regular maintenance and repairs, we are able to ensure that all components of the hydraulic cone reamer are in working condition and reduce the failure rate due to wear or aging. This not only improves the stability of the equipment, but also extends its service life. At the same time, stable equipment performance means stable production capacity, which can ensure the continuity and efficiency of the production process. However, if equipment is not properly maintained or fails, the consequences can be serious. The occurrence of failures may lead to production interruptions and even cause safety accidents. This will not only affect production plans, but may also cause economic losses to the company. Therefore, paying attention to the maintenance status of the equipment and carrying out regular maintenance and repair are important measures to ensure the stability of the production capacity of hydraulic cone reamers.

In conclusion, the production capacity of hydraulic cone reamers (model: lk/yzv180) is relatively stable under normal circumstances, but it is also affected by various factors such as materials, operation and maintenance. Therefore, in order to ensure the stability of production capacity, users need to select high-quality materials, improve the skill level of operators, and carry out regular equipment maintenance and overhaul. -

04. 07. 2024How does the hydraulic pre-roll forming machine achieve rapid forming of storage tanks?View more

The hydraulic pre-coil and flanging machine enables a fast flanging process of the tank. This is a comprehensive process that integrates precision mechanical operation, hydraulic drive and electrical control technology. Here are some detailed answers on how to achieve quick flanging of the tank:

First, the heart of the machine lies in its unique pre-roll flanging mechanism. This mechanism is well designed and can be precisely adjusted to the shape and size of the tank to ensure smooth flanging operations. The pre-roll flanging mechanism comes into play when the tank is placed on the machine's workbench.

Secondly, the hydraulic drive system plays a vital role in the entire flanging process. The system uses high-pressure hydraulic fluid to drive a pre-roll capping mechanism to achieve rapid capping of the lower end of the tank. Since the hydraulic system has the characteristics of large output force and smooth movement, it can ensure the stability and accuracy of flanging operation.

In addition, the electrical control system also provides strong support for quick flanging. As the brain of the entire machine, the PLC control system is responsible for receiving and processing various sensor signals and controlling the action of the hydraulic drive system according to preset programs. With precise control, the PLC system is able to ensure the sequence and coordination of stamping operations, thereby improving production efficiency.

At the same time, the machine also adopts advanced solenoid valve driving technology. Compared with traditional relays, solenoid valves have the advantages of rapid response and high control accuracy. This allows the machine to respond to instructions more quickly during the stamping process, achieving precise control of stamping speed and accuracy.

, operators also play an important role in the entire process. They can monitor and adjust the machine in real time through the control panel or touch screen to ensure that stamping operations are carried out as expected. Once stamping is complete, the machine will automatically stop working and a prompt signal will be sent to inform the operator of the next step. In summary, the hydraulic pre-bending and flanging machine Lk/Yzf180-2 achieves rapid flanging of the tank body through its unique pre-bending and flanging mechanism, hydraulic drive system and electrical control system. During this process, the various parts of the machine cooperate with each other to ensure stability, accuracy and efficiency in flanging operations, and to improve production efficiency and quality. -

04. 05. 2024In a pneumatic four-wheel tank sealing machine, what is the function of the sealing head?View more

The sealing head is a key component of the pneumatic four-wheel tank sealing machine. Its function is to form a sealed state between the tank cover and the tank body. It plays a vital role in ensuring the integrity, safety and freshness of packaged products.

Contact points with the tank and lid: The sealing head acts as a contact point between the tank and the lid during the sealing process. On passing the sealing means, it cooperates with the tank and the lid to form a secure seal by applying pressure. The design and construction of the sealing head is essential to achieve a stable and reliable seal of tanks of different sizes and materials.

Roller or wheel configuration: The sealing head is usually composed of multiple sets of rollers or wheels arranged in a specific configuration to press and seal the lid on the tank. These rollers or wheels exert pressure on the lid, causing it to bend at the flange of the tank and form a tight seal. The arrangement and orientation of the rollers/wheels may vary depending on the design of the sealing head and the sealing requirements of the application.

Adjustability for different jar sizes: Many pneumatic four-wheel jar mouth sealers are equipped with adjustable sealing heads that can accommodate different jar sizes and lid types. The operator can easily change the settings of the sealing head to suit the size of the can being processed, thus ensuring compatibility with various packaging requirements.

Precision and consistency: The sealing head must remain in precise and stable operation in order to create a high-quality seal on every can. Proper alignment and calibration of the sealing head is essential to ensure uniform pressure distribution and seal integrity over the entire circumference of the can. Deviations or inconsistencies in the operation of the sealing head can lead to reduced seal quality and product quality issues.

Sealing Pressure Control: The sealing head applies controlled pressure to the cover, resulting in a seal that can be achieved. A pneumatic cylinder or actuator connected to the sealing head provides the necessary pressure during the sealing process. The sealing pressure can be adjusted to the requirements of the packaging application to ensure that the seal is neither too loose nor too tight.

Sealing speed and efficiency: In addition to pressure control, the sealing head also affects the speed and efficiency of the sealing process. The design of the sealing head, including the number and arrangement of rollers/wheels, determines the degree of sealing speed that can be achieved without reducing the sealing quality. A properly designed sealing head can greatly shorten cycle time and improve production efficiency, thereby improving overall efficiency and productivity.

Compatibility with lid types: The sealing head must be compatible with a variety of lid types, including standard metal lids, easy-open lids, and composite lids. Different cap materials and designs may require specific adjustments or configurations of the sealing head to ensure good sealing performance. Compatibility with a wide range of lid types increases the versatility of sealing machines and gives them wider applicability across different industries and product categories. -

03. 29. 2024What is the function of the pneumatic system of the pneumatic four-wheel tank mouth sealing machine?View more

Pneumatic systems play a vital role in the operation of pneumatic four-wheel sealing machines, providing the necessary power and control for the sealing process. The pneumatic system consists of various pneumatic components such as cylinders, valves and actuators, which enable the machine to complete sealing operations efficiently and reliably.

Power supply: The primary function of the pneumatic system is to generate the power required to operate the sealing machine. The pneumatic system uses compressed air as the power source, which is stored in compressed air tanks or provided by external air compressors. Compressed air is then delivered to different pneumatic components of the machine, such as cylinders and actuators, to drive its movement and apply forces as needed for the sealing process.

Drive of the sealing head: A key function of the pneumatic system is to drive the sealing rings, which are responsible for sealing the jars. The sealing ring is usually formed by multiple sets of rollers or wheels arranged in a specific configuration to press and seal the can lid to the can body. A pneumatic cylinder or actuator applies the necessary force to bring the seal into contact with the can and can lid, ensuring a tight and secure seal.

Control of sealing pressure and time: The pneumatic system enables precise control of sealing pressure and time, ensuring that the seal of each tank reaches a consistent and high-quality standard. By adjusting the air pressure supplied to the pneumatic cylinder or actuator, the operator can adjust the amount of force applied during the sealing process. In addition, pneumatic valves and control circuits control the timing of the sealing operation so that the action of the sealing head is coordinated with the time it takes for the can to reach the sealing station.

Adjustment of sealing parameters: Pneumatic four-wheel canning machines usually have adjustable sealing parameters to accommodate different tank sizes, lid types and sealing requirements. The pneumatic system enables the operator to easily adjust parameters such as seal pressure, speed and stroke length to optimize the sealing process according to specific production needs.

Safety Interlocks and Emergency Stop Devices: Pneumatic systems also have another important function, which is to achieve safety features such as interlock and emergency stop mechanisms. Pneumatic valves and actuators control the activation of the safety device to ensure the safe and reliable operation of the sealing machine. In the event of an emergency or malfunction, the operator may initiate an emergency stop procedure to stop the machine from operating, thereby avoiding potential danger or damage.

Energy efficiency and cost savings: Pneumatic systems are distinguished by their excellent energy efficiency and cost-effectiveness compared to hydraulic or electric systems. By using compressed air as the power source, pneumatic four-wheel sealing machines can achieve high power and high performance while significantly reducing energy consumption. Furthermore, pneumatic components are generally more economical and easier to maintain than hydraulic or electric components, resulting in a reduction in the overall operating cost of the machine. -

03. 22. 2024How does the sealing performance of this special shape sealing machine?View more

As a special processing equipment in metal tank plants, this specially shaped sealing machine plays a key role in the crimping and forming process. Its sealing performance directly affects the quality and service life of the final product. The sealing performance and related aspects of this special shape sealing machine will be described in detail below.

Mechanical structure design: Sealing machines with special shapes usually adopt a precise mechanical structure in the design to ensure a tight fit between the components. This design helps reduce sealing gaps, thereby improving sealing performance.

Material selection: The materials used in sealing machines usually have good sealing performance. For example, critical components such as gaskets and sealing rings are typically made of rubber, silicone, or other highly elastic materials to ensure that the gap between the tank and the sealing component can be effectively filled and sealed during the sealing process.

Pressure Control: During the sealing process, the sealing machine usually applies pressure to ensure the sealing effect. With a precise pressure control system, the sealing pressure can be effectively controlled to be just right, so that the sealing effect can be guaranteed without damaging the tank or sealing components.

Sealing process: Sealing machines usually use a series of precise process steps to complete the sealing process, such as pre-pressing, forming, pressing, etc. These process steps effectively ensure a tight bond between the sealing component and the tank body, thereby improving sealing performance.

Sealing Performance Testing: During the production process, sealed products are usually tested for sealing performance to ensure that they meet relevant standards and requirements. Common testing methods include pressure testing, vacuum testing, watertightness testing, etc. These tests enable the sealing performance of the product to be assessed and potential problems to be identified and resolved in a timely manner.

Maintenance: Regular maintenance is essential to maintain the sealing performance of your sealing machine. Including cleaning, lubrication, replacement of seals, etc., these measures can effectively extend the service life of the sealing machine and ensure that its sealing performance is always maintained.

The sealing performance of special shape sealing machines can be affected by many factors, including mechanical structure design, material selection, pressure control, sealing technology, sealing performance testing, and maintenance.

-

03. 15. 2024How to evaluate the performance and quality of automatic winding and sealing machines?View more

Evaluating the performance and quality of automatic winding and sealing machines is a key step in ensuring efficient production line operation and product packaging quality. Here are some common methods and metrics that can be used to evaluate the performance and quality of automatic winding and sealing machines:

Packaging speed and production capacity: Packaging speed is one of the important indicators to measure the performance of automatic winding and sealing machines. Faster speed means shorter production cycles and higher production capacity to meet changing market demands.

Sealing quality: Sealing quality is directly related to the packaging integrity and protection performance of the product. When assessing the quality of the seal, it is necessary to check whether the seal is secure and tight, and whether there is air or liquid leakage. Through qualitative and quantitative analysis of sealing quality, the sealing performance of automatic winding sealing machines can be evaluated.

Stretch uniformity: Automatic packaging machines typically stretch the packaging material during the packaging process to ensure that the package fits snugly against the product surface. Evaluating stretch uniformity can check whether the material is stretched evenly, thereby avoiding packaging quality problems caused by uneven stretching of the material.

Stability and reliability of equipment: The stability and reliability of equipment is one of the important indicators for evaluating equipment quality. Stability refers to the stable performance of equipment during long-term operation, while reliability refers to the frequency of equipment failures during production and maintenance needs. By testing and evaluating the stability and reliability of the equipment, it can be determined whether the equipment can meet production needs and have a good service life.

Operating convenience: Equipment operating convenience is one of the important aspects in evaluating equipment performance. Operational convenience refers to whether the equipment is easy to operate and adjust, and can be quickly adapted to different production needs. By evaluating the device's operating interface, adjustment methods, and human-computer interaction methods, the device's operating convenience level can be determined.

Energy consumption: Energy consumption is one of the important aspects in evaluating the performance of automatic winding and sealing machines. Energy-saving equipment can effectively utilize energy resources, reduce production costs and reduce environmental impact. By evaluating the energy consumption level of the equipment, its energy-saving performance can be determined and energy cost analysis can be performed.

Applicability and flexibility of the product: The suitability and flexibility of the equipment is one of the important indicators for evaluating its performance. Equipment that can be adapted to a variety of product types and sizes can meet different production needs and have high production flexibility. By evaluating the suitability and flexibility of equipment, it is possible to determine its scope of application and the degree of production flexibility.

-

03. 08. 2024What is the parallel operation mechanism of the semi-automatic cylindrical canning machine?View more

The parallel operation mechanism of the semi-automatic round can sealing machine is a technical means to enable the equipment to process multiple round cans at the same time. Through rational design and process flow, the sealing machine has the ability to process multiple round cans simultaneously, thereby improving production efficiency and capacity utilization. The following is a detailed analysis of the parallel operation mechanism of the semi-automatic round can sealing machine:

Multi-station design: This semi-automatic round can sealing machine adopts a multi-station design, that is, multiple working positions are set on the equipment, and each working position can independently complete the sealing operation. In this way, a plurality of round cans can be placed in different working positions at the same time, thereby achieving parallel processing of the round cans.

Synchronous action control: The parallel operation mechanism requires that the sealing action of each working position can be carried out synchronously to ensure that the sealing operation can be completed simultaneously in each round. Through the precise control system and transmission device, the semi-automatic round can sealing machine can achieve synchronization and coordination between various working positions, so that the round can can be sealed at the same time in different working positions.

Segmented operation: In the design of semi-automatic cylindrical canning machines, the equipment is usually divided into different areas, each corresponding to a working position. In this way, the operator can operate simultaneously in different areas, place multiple cans in their respective working positions, and uniformly start the sealing action through the equipment control system, thereby achieving synchronous sealing of multiple cans.

Process optimization: Different sealing process flows can be rationally optimized and designed. For example, some processes that take a long time can be assigned to specific jobs, while some processes that are completed quickly can be assigned to other jobs, thereby balancing the sealing time between various jobs and improving overall production efficiency.

Operator cooperation: The implementation of the parallel operation mechanism also requires close collaboration among operators. Operators need to reasonably arrange the placement of the round cans according to the instructions of the equipment, and monitor the sealing process of each working position in a timely manner after the equipment is started to ensure that each round can can successfully complete the sealing operation.

Stability and reliability of equipment: Implementing a parallel operation mechanism also requires sufficient stability and reliability of the equipment itself. Sealing quality and production efficiency at each working position can only be guaranteed if the equipment can maintain stable performance during long-term operation.

-

03. 01. 2024How does a semi-automatic round can sealing machine seal multiple round cans at the same time?View more

As a common sealing device, semi-automatic round can sealer plays a vital role on the production line. In order to improve production efficiency, it is sometimes necessary to have the sealing machine seal multiple round cans at the same time. Here are some key methods and strategies for semi-automatic round can sealers to handle multiple cans simultaneously:

Multi-station design: Design a semi-automatic round can sealing machine with multiple sealing stations to process multiple round cans at the same time. Each station is equipped with an independent system for controlling the sealing and sealing actions, so that the operations between different stations do not interfere with each other and the sealing operations can be carried out independently.

Synchronous action control: Through advanced control system, synchronous control of sealing action between different stations is achieved. After setting the sealing parameters and working rhythm, the control system can ensure that the sealing action of each station is carried out simultaneously, thereby achieving synchronous sealing of multiple cans.

Parallel operation mechanism: With the parallel operation mechanism, operations between multiple workstations can be carried out simultaneously without interfering with each other. For example, it may be designed so that when packaging for one round is in progress, packaging for another round may be placed or removed to ensure continuity and stability of the production line.

Segmented Workflow: Break down the sealing process into multiple steps and process multiple jars simultaneously in each step. For example, steps such as placing, positioning, sealing, and removing the round can can be arranged to be performed at different workstations, and these steps can be performed simultaneously to improve production efficiency.

Optimized mechanical structure: An optimized mechanical structure was designed to meet the needs of handling multiple round cans simultaneously. For example, a rotary table or conveyor belt conveying system may be used to move and handle multiple cans simultaneously on the can sealer, thereby improving production efficiency.

Appropriate adjustment of sealing parameters: In view of the practical situation of processing multiple round cans at the same time, the sealing parameters should be appropriately adjusted to ensure sealing quality and stability. For example, parameters such as pressure, temperature, and sealing time of the sealing head can be adjusted to accommodate round cans of different sizes and shapes.

Regular Maintenance and Care: The semi-automatic round can sealer is regularly maintained and serviced to ensure the normal operation and stability of the equipment. Efficient and high-quality sealing of multiple round cans can only be guaranteed at the same time when the equipment is in good working condition.

-

02. 23. 2024What are the applications of hydraulic square canning machines in the food processing industry?View more

As one of the important equipment in the food processing industry, hydraulic square canning machines have a wide range of applications. From simple food canning to complex packaging processes, hydraulic square canning machines play an important role. The following will explore the specific application scope of hydraulic square canning machine in food processing industry.

Canning of vegetables and fruits: Hydraulic square canning machines play an important role in the canning process of vegetables and fruits. By means of the high pressure provided by the hydraulic system, vegetables and fruits are able to be pressed and sealed sufficiently in the tank, thus extending their shelf life and preserving their nutritional content and taste. Various fruits and vegetables, such as peaches, cherries, oranges, carrots, corn, etc., can be processed through hydraulic square canning machines to meet market demand.

Canning of meat and seafood: Hydraulic square canners are also widely used in canning of meat and seafood. Through the pressure action of the hydraulic system, meat and seafood can be completely compressed and sealed in the can to ensure the freshness and hygiene safety of the product. Various meats, such as chicken, beef, pork, and various seafoods, such as fish, shrimp, shellfish, etc., can be canned using hydraulic square canners to meet consumers' demand for convenience foods.

Canning production of dairy products and soy products: Hydraulic square canning machines also play an important role in canning production of dairy products and soy products. Through the high pressure action of the hydraulic system, dairy products and soy products can be fully compressed and sealed in cans, thereby extending their shelf life and maintaining their nutritional composition and taste. For example, various dairy products such as milk, soy milk, milk powder and soy products such as tofu, soy milk, etc. can be canned by hydraulic square canning machines to facilitate consumers to eat them at any time.

Canning of pastries and candies: Hydraulic square canning machines also have important applications in canning pastries and candies. Through the pressure provided by the hydraulic system, various pastries and candies can be fully pressed and sealed in cans, thereby extending their shelf life and facilitating storage and transportation. Various kinds of pastries such as cakes, cookies, candies, etc., as well as various kinds of candies such as chocolate and candy beans can be canned by hydraulic square canning machines, providing consumers with convenient and fast food choices.

Canning Production of Condiments and Sauces: Hydraulic square canning machines are also widely used in the canning production of condiments and sauces. Through the high pressure action of the hydraulic system, various condiments and sauces can be pressed and sealed in the tank sufficiently to maintain their flavor and aroma. Various condiments such as soy sauce, vinegar, sauces, etc. can be canned by hydraulic square canning machines, providing consumers with condiments that are easy to carry and use.

-

02. 16. 2024What are the environmentally friendly features of hydraulic square canning machine?View more

In today's environmentally conscious society, all walks of life are striving to find greener solutions. As one of the important equipment in the food processing industry, the hydraulic square canning machine also has unique characteristics and advantages in environmental protection.

First, the hydraulic square canning machine uses a hydraulic system during the processing, which is more energy-efficient than traditional mechanical systems. The hydraulic system transmits power by compressing the liquid. Compared with mechanical transmission, it can reduce energy waste and energy consumption, thereby reducing negative impacts on the environment.

Secondly, hydraulic square canning machines usually have a high degree of automation and can realize automated production operations. Equipped with an advanced control system, the hydraulic square canning machine can realize automatic monitoring, automatic adjustment and automatic control of the production process, reducing human intervention and reducing the probability of human error and production accidents. This not only improves production efficiency, but also reduces unnecessary waste of resources and energy consumption, which is beneficial to environmental protection.

In addition, the principles of energy saving and environmental protection are usually taken into account in the design and manufacture of hydraulic square canning machines. Modern hydraulic square canning machines often use advanced materials and processes, which have a long service life and low maintenance costs. At the same time, in order to reduce noise and vibration and reduce pollution to the environment, hydraulic square canning machines are usually designed with sound insulation, shock absorption and other measures in mind, so that the noise and vibration generated during the operation of the equipment can be effectively controlled without affecting the surrounding environment and work.

, hydraulic square canning machines are usually able to make full use of raw materials and reduce waste generation during processing. Through precise pressing and mold design, the hydraulic square canner can ensure sufficient compaction of raw materials, reduce the generation of waste and by-products, improve production efficiency and raw material utilization, and reduce resource waste and environmental pollution.

Hydraulic square canning machine has many characteristics and advantages in environmental protection. Its efficient energy use, automated production processes, energy-efficient and environmentally friendly design, and full utilization of raw materials can help reduce negative impacts on the environment, improve production efficiency and resource utilization, and make a positive contribution to the sustainable development of the food processing industry.

- Mobile: +86-13666712509

- Tel: +86- 0573-8802501

- Email: yuequ@lkmach.com

- Whatsapp: +86 136-6671-2509

- Address: No. 5, Huatian Road, Siqian Community, Cengang Street, Dinghai District, Zhoushan City, Zhejiang Province

- Home

- About us

- Product

- Convenient barrel production line

- 18 L Square Tank Production Line

- 1-5 liter square tank production line

- 1-5 liter round can production line

- Tea cans, craft cans (square cans)

- 18.5 Conical coating barrel production line

- 18.5 Straight Paint Bucket Production Line

- Vacuum cleaner [housing] complete set of equipment

- 50 L Chemical Barrel Production Line

- Forming mold

- Can lid production line

- 18-20 liter barrel production line

- Service

- News

- Contact Us

- Convenient barrel production line

- 18 L Square Tank Production Line

- 1-5 liter square tank production line

- 1-5 liter round can production line

- Tea cans, craft cans (square cans)

- 18.5 Conical coating barrel production line

- 18.5 Straight Paint Bucket Production Line

- Vacuum cleaner [housing] complete set of equipment

- 50 L Chemical Barrel Production Line

- Forming mold

- Can lid production line

- 18-20 liter barrel production line

EN

EN

中文简体

中文简体 English

English