When designing tin cans

Canned food products discontinued and destroyed

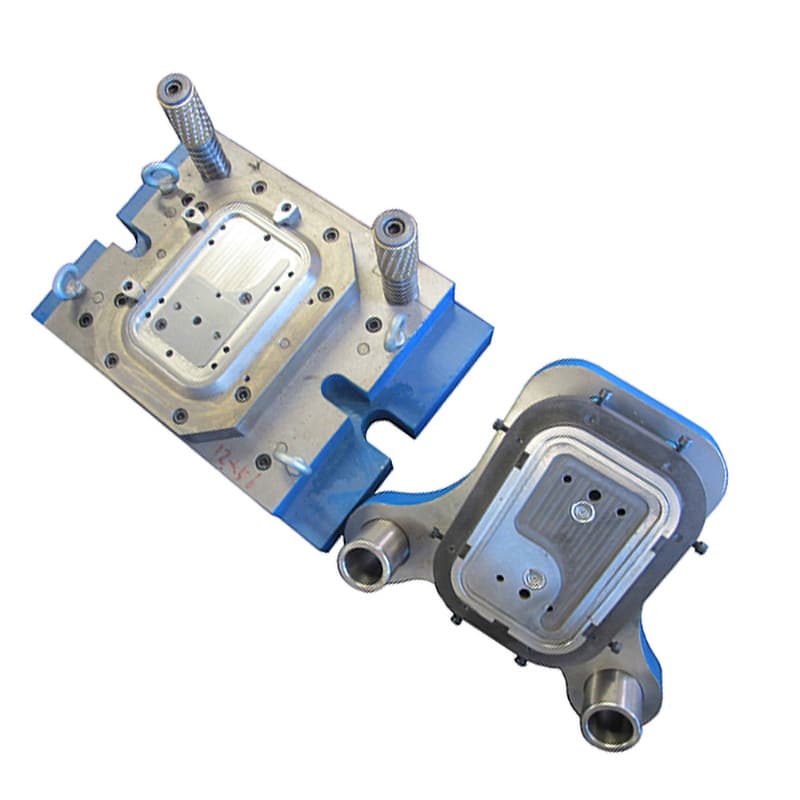

When designing a metal can, there are several factors to consider when choosing a mold. The mold must allow the molten metal to flow smoothly into the cavity of the mold and facilitate the removal of the solidified casting from the mold. If there are complex features on the part, additional mold parts may be required to fit. Generally, the mold insert is slid into the part cavity from one side of the mold. These inlays are called side inlays or slides.

Modern die manufacturing technology enables the production of dies and stampings with micron-level accuracy. The materials used are high-speed steel and cemented carbide. In addition, other materials such as ceramics are also adopted. CNC machining processes enable dies and stampings to be machined into specific shapes, ensuring that the product always has the same quality. Therefore, dies and stampings are used to manufacture large-scale products with high quality and consistency.

The die casting process uses a special steel with heat resistance properties. The mold consists of two parts that together form a cavity for containing liquid metal. The two parts are held together by a fixed or movable plate. High pressure is applied during the casting process. To ensure the mold is stable, a lock is installed on the mold. This prevents damage to the mold. These molds are not only very durable, but also deliver quickly.

Die casting unions complete subsequent processes such as gluing, polishing, plating, sanding and painting. Among various lubricants, water-based lubricants are widely used. Water-based lubricants have environmentally friendly properties and are also an option for many health and safety reasons. They do not contain harmful by-products and are safe to use. In addition, the water-based lubricant does not leave residues in the mold. However, if not handled properly, water-based lubricants may develop surface defects.

Once the molten metal enters the mold cavity, it begins to solidify. Then, when the casting has completely solidified, the mold must be reopened to remove it. The time required for the casting to cool depends on the type of metal used for the mold and the thickness of its walls. The thickness of the casting will also depend on the complexity of the mold and its geometric complexity. In addition, complex moulds may create additional obstacles to the flow of heat.

Steel scale tools are another type of metal mold. It can be used for softer materials, such as thin steel sheets. The cutting face of the steel scale tool is the edge of a hardened steel strip with laser-cut grooves located on the die. This steel die is pressed into the workpiece (usually the parent structure). By using a plurality of cavity molds, a plurality of identical cavities can be formed.

4 L Square Can Lid Mold Step 01

LK Machinery is known for combining industry, trade and technology. Chinese products owned in can forming molds and can parts molds and molds. We specialize in the production of metal packaging equipment and the design of forming machines. We have a strong research and development team and are able to develop and produce products based on drawings or samples provided by customers. We can select and recommend suitable production line according to customer's needs. We are a trading company with our own manufacturing plant, engaged in the production of metal packaging machines, equipment and molds. Our annual machine production reaches 500 units and mold production exceeds 1000 units. We are able to fully meet the needs of our customers. Custom cans, can lids, rings, can bodies, lids, and bottom lids can all be simpler and faster.

Recommended Products

EN

EN

中文简体

中文简体 English

English