Tin can molds are important equipment for manufacturing tin cans.

Canned food products discontinued and destroyed

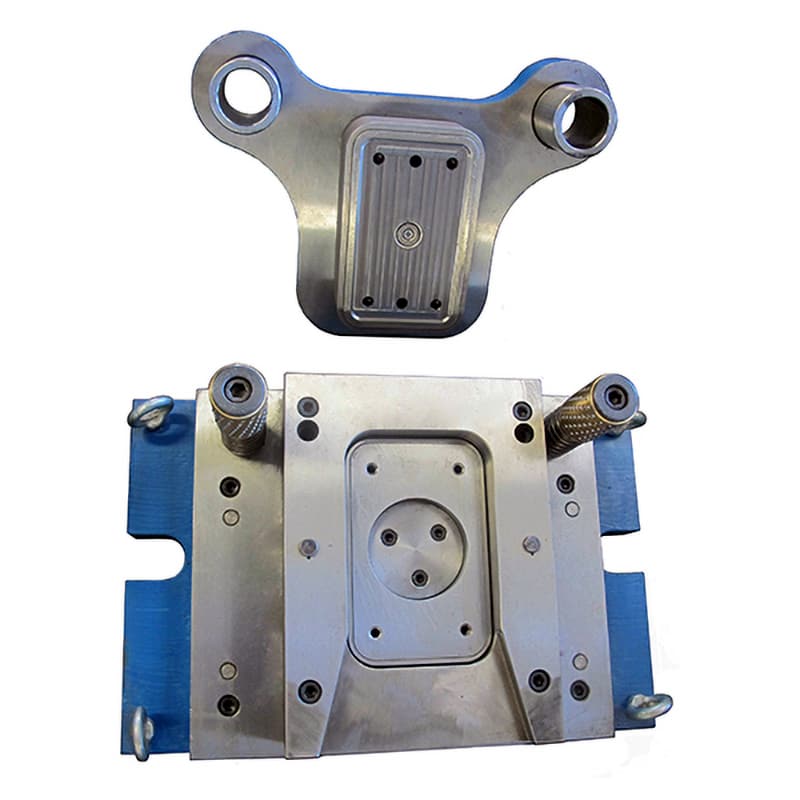

Can molds and can forming machines are important equipment used to make cans. These devices are used to produce cylindrical cans of different sizes. The production process involves stamping the cup into shape through a single or multiple dies. These molds are designed to reduce the thickness of the cup while maintaining the same diameter. This process is repeated two or three times to complete each can.

Tool materials and cutting geometry are often affected by the hardness of the workpiece. Additionally, different repair methods are used for damaged surfaces. In some cases, machining of damaged surfaces requires the use of cutting tools to remove layers of material with hard and soft layers. This shortens the life of the tool, so the tool manufacturer must compensate for this.

The material cost of a mold depends on its thickness and material density. In addition, it depends on the type of material used for the component. The thinner the components, the higher the cost. Thinner parts require larger channels so that the material can fill in faster. In most cases, the amount of additional material used is less than the amount of material saved by reducing the volume of the component.

The casting process uses a mold to shape the metal product. The molten metal is then injected into the mold. The resulting product is called a casting. This process is described in more detail below. When choosing a mold for casting, you should consider your own needs. The mold can produce high-quality products.

Depending on your needs, dies and stampings can be made from a variety of materials. For example, tool steels with high carbon content are often chosen because they can withstand hundreds of thousands of cycles. In addition, the mold material can also be made from other metals, including vanadium and tungsten.

The mold making process is a complex process that requires special consideration and design solutions. This may involve the use of complex materials, complex shapes, and different processing strategies. The manufacturers will know how to anticipate these needs and ensure that their products can meet them. They are committed to meeting the needs of the mold and die manufacturing industry with innovative and efficient solutions.

The process of die casting is to press the molten metal into the cavity of the mold under high pressure. The mold is made of quenched tool steel and usually consists of two parts with a cavity inside that holds the liquid metal. Molds are carefully manufactured to form precise parts to specifications.

LK Machinery is known for combining industry, trade and technology. We specialize in can forming molds and can parts molds and molds, and are particularly good at the production of metal packaging equipment and the design of forming machines. We have a strong R & D team that can develop and produce products based on drawings or samples provided by customers. We can select and recommend suitable production line according to customer's needs. We are a trading company with our own manufacturing plant, engaged in the production of metal packaging machines, equipment and molds. Our machines can produce up to 500 units per year and more than 1000 pieces of molds per year. We are able to fully meet the needs of our customers. Custom cans, can lids, rings, can bodies, lids, bottom lids, etc. can all be completed more easily.

Recommended Products

EN

EN

中文简体

中文简体 English

English