Selecting equipment for canning machinery plants

If you are planning to start a canning factory, then you need to choose a machine that is easy to operate. It should be accompanied by clear instructions for use and require no specialized technical knowledge. Modern machines are more advanced than ever, and most of their functions are fully automated. Some machines are capable of doing all the work even of humans.

You can buy a set of automatic cone barrel can production line from a reputable manufacturer. The production line includes a tank feeder, an automatic piping machine, an automatic taper forming machine and an automatic bottom cover sealing machine. The machine is easy to operate and has a variety of functions, including a complete automation system.

The main function of a cannery is to produce cans. These cans are widely used in commodity packaging and are safe and reliable. However, the production process for cans can be costly when large quantities are required. Therefore, canning plants would be more cost-effective. But you have to make sure you choose a machine that produces cans.

The shape of the can determines its design. Traditionally, cans have a printed label on top. Some cans also have extra information printed on the can, such as a recipe. There are also cans with rounded corners. You can buy cans in various shapes, such as soup cans, tuna cans, or sardines cans.

When choosing a machine for your cannery, you should look for a manufacturer with extensive experience in the industry. Experienced companies are able to provide you with a complete set of canning equipment, as well as molds and other materials. In addition, you can purchase a complete set of food components.

You can also choose a production line dedicated to the production of small round cans. These machines are designed to be both quiet and efficient. Some are even equipped with automatic tank conversion devices. Automatic small round tank production line factory will also integrate automatic tank rack and flanging device. Both features help you produce square cans.

A can manufacturing plant is able to complete the following processes: shearing, grooving, drying, coating and can making. Yixin Technology's strong technical team and professional production staff will help you build the canning production line. For the first two processes, the tank body is first placed in the groove plate and then sent to the feed roller. Next, the processing is carried out by resistance welding equipment.

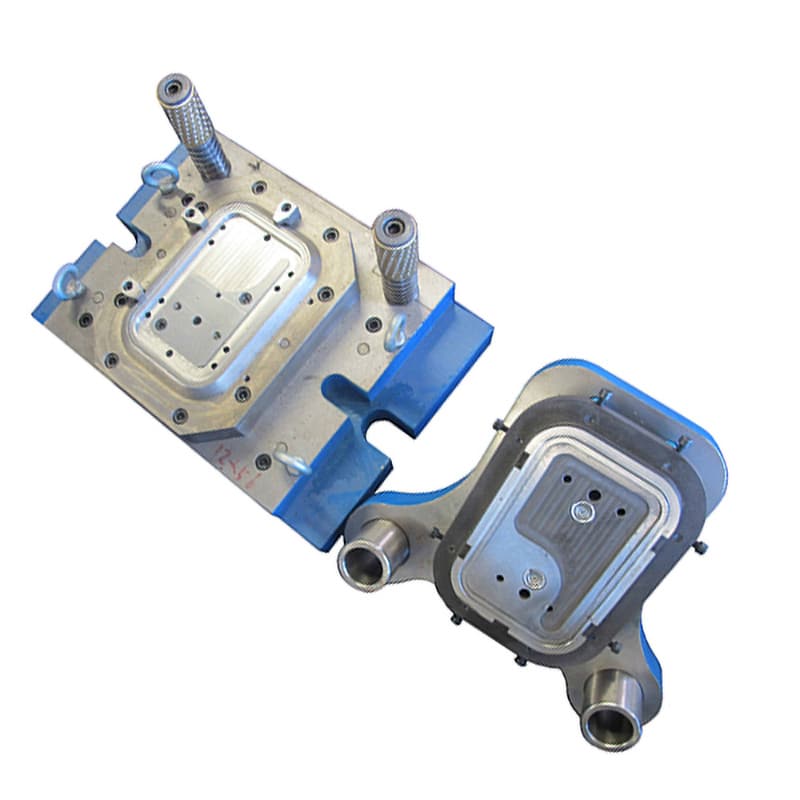

LK Machinery is known for the integration of industry, trade and technology. As a tin can forming mold and tin can component mold manufacturer in China, we focus on metal packaging equipment production and forming machine design. With strong R & D team, we can develop and produce products according to the drawings or samples provided by customers, and can select and recommend suitable production lines according to customer needs. As a trading company with our own production plant, we specialize in metal packaging machinery, equipment and mold manufacturing. The annual production of machinery and equipment reaches 500 units, and the output of molds exceeds 1,000 sets, which can meet customer needs. Custom tin cans, can lids, can rings, can bodies, can lids, can bottom lids and other products can all be easily realized.

Recommended Products

EN

EN

中文简体

中文简体 English

English