Can flanging machines can be divided into two categories

Flange machines can be manufactured from 304# stainless steel. The machine is designed to be durable and dust and rust resistant. At the same time, it is also compatible with automatic sealing machines. This means it can produce jars in different sizes, from small to large.

Edge folding machines are divided into two categories, namely crushing type and edge folding type. The broken type is typically used to make jars of irregular size, while the hemmed type is a machine specifically designed for hemming round jars. During the hemming treatment of the can, the hemming die is fed along the axial direction of the can body. A series of rollers will be hit by the hemming die, and the tank will complete the hemming process under the action of extrusion.

The punching machine is designed so that it can punch both sides of the tank. For example, a can may have a bottom flange and a top flange. Both flanges must be formed during the stamping process. The width of the flange must not be uneven and the jar must be flat and free of cracks. And the coating of the can must be properly cured. The quality of the flange is poor if the coating is blistered, or if the can body is folded inwards.

Some tin can piping machines include a piping machine, a tank welding machine, and a tank sealing machine. These machines are all capable of producing jars of various shapes. But piping is often used to make jars of various shapes.

This piping forming machine can be used to form a circle of flanges around the tank body. Piping is a process used to enhance the strength of a tank. Additionally, the piping process helps create jars with larger diameter profiles. There are also lid making machines available, which are able to complete processes such as cross stamping, paper feeding, and forming.

The necked type is a common edge forming method. During the rimming process, the rimming die protrudes from both ends of the tank body. The tank is then extruded to finally form flanges at both ends of the tank. The edge forming process can be completed in one go or in several steps.

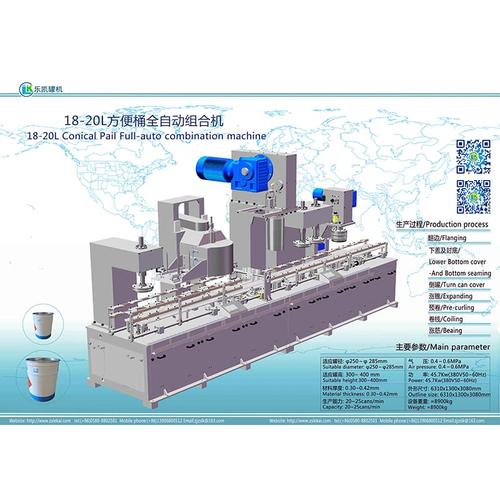

Depending on the type of flanging and its size requirements, the flanging machine can be personalized. The flanging machine can be used in connection with an automatic sealer or it can be set up to produce jars with necks and lids.

Recommended Products

EN

EN

中文简体

中文简体 English

English